The Best of Both Worlds – Standard Tooling and a Custom Interior in Blow Molded Plastic Cases

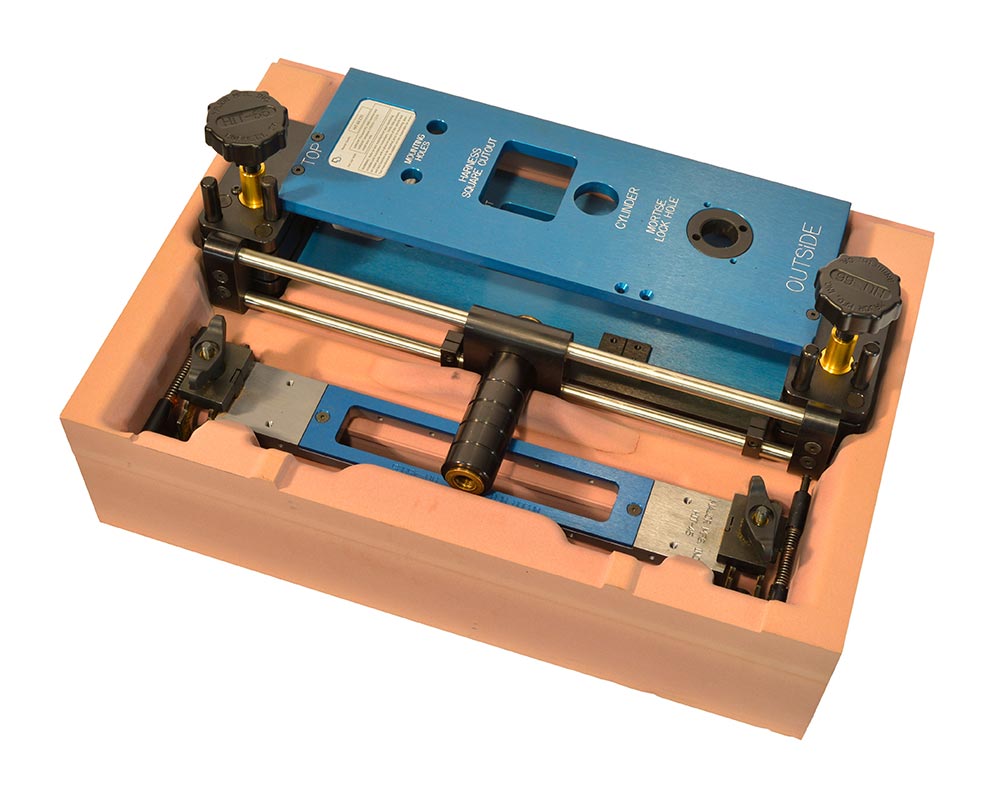

All PFC standard case molds utilize some variant of our modular tooling system enabling us to offer our customers over 125 stock cases sizes to work with.

By combining our standard mold tooling with components designed for your specific needs, we can create a unique blow molded case for much less than the cost of building a custom mold. How much less? On average, this approach can reduce tooling costs by 80% to 90%, and you still enjoy all the benefits of our double-wall construction.

*MINIMUM QUANTITIES APPLY

Superior Durability in Blow Molded Cases

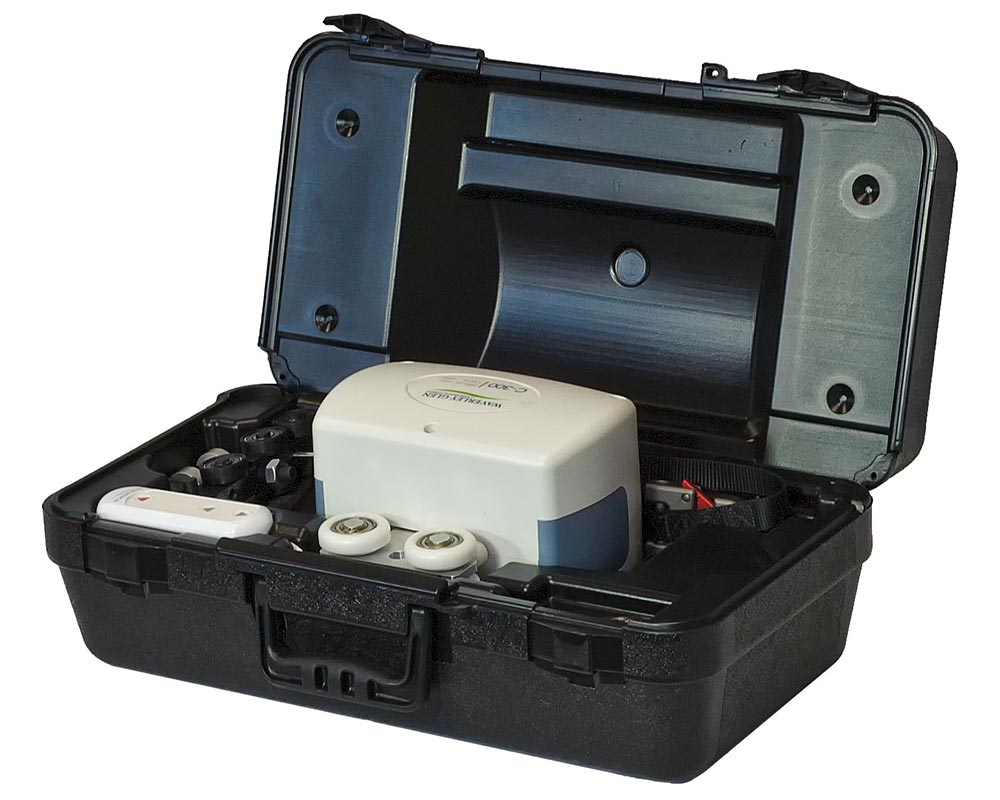

Our blow molded plastic cases with custom molded interiors boast unrivaled product protection, enticing display options, enhanced space efficiency, and unparalleled durability. Our signature blow molded case interior is not a mere insert; it’s seamlessly integrated into the case. This design ensures that our blow molded cases with custom molded interiors are competitively priced, closely rivalling our Stock Carrying Cases in terms of cost.

Made in USA Molded Case Features

We further enhance the value of our made in USA molded cases with features such as distinctive colors, meticulously tailored cut outs, pockets for literature and manuals, and custom logos and labels. If you’re looking for a blow molded case with a custom label and interior, our extensive range of designs will certainly impress.

- From design to delivery in as little as 4-6 weeks

- An extensive range of value-added enhancements available

Click the arrows below to view additional images of modular tooling and molded interiors.

Efficient Use of Space with Blow Molded Plastic Cases

Made in USA blow molded cases with custom molded interiors optimize space better than their counterparts. Our adept design team excels in packaging products in the smallest blow molded case, leading to reduced costs and saving warehouse space, all while lowering shipping expenses.

Brand Consistency & Simplification with Blow Molded Cases

When dealing with various product versions, we can typically design a single blow molded case with foam interior to accommodate all. By doing so, we streamline inventory management and trim down costs. For product lines requiring multiple case sizes, our unique modular mold system assures brand consistency across all made in USA blow molded cases.

Strong & Durable Blow Molded Plastic Cases

All our cases, are made from recyclable high-density polyethylene (HDPE). This material offers superior impact strength, resistance to solvents and oils, and unmatched durability. Color is integrated directly into our blow molded cases, ensuring longevity without chipping or peeling. Additionally, our Mold-Tech™ exterior finish remains scratch-resistant, ensuring our cases retain their aesthetic appeal. Plus, our patented mechanical hinges and latches set the industry standard.

Made in America Blow Molded Cases

We pride ourselves on handling everything in-house — from design and mold engineering to manufacturing — and we do it all right here in the USA. We don’t compromise by subcontracting or outsourcing. This commitment ensures meticulous attention to detail and swift lead times of just 4-6 weeks. Our goal is to provide a distinctive, cost-effective custom package promptly. As industry leaders, we believe custom blow molded cases shouldn’t be burdensome or exorbitant.

Value-Added Customizations

Interior Customizations

Exterior Customizations

-

Standard and Custom Colors

-

Full Color Labels

-

3D Logo

Request More Information

Interested in finding out how PFC can help you?

Use the form below to have a PFC rep contact you. You can also opt to receive our digital brochure via email link to the email you provide.