Blog Post

PFC Has You Covered

At PFC, we understand that every product deserves a case that’s as precise and dependable as the items it protects. That’s why our custom design process begins with a conversation—because your needs drive our innovation. From initial part scanning to final production, our streamlined workflow combines cutting-edge technology with expert craftsmanship to deliver tailored solutions that fit your specifications perfectly. Whether you’re looking for foam inserts or molded interiors, PFC has you covered—every step of the way.

When PFC receives a new request, we like to begin with a conversation to learn about any requirements for their product or case specifications. Working with the actual parts helps us to design the best fit and when that is not possible we have solutions to help configure your case to the exact specifications required.

Scan the Parts

With our High Resolution Scanner your parts are scanned by our design team, saving time in the engineering process while providing incredible accuracy. The models generated by the 3D Scanner will be used to design the custom case interior.t.

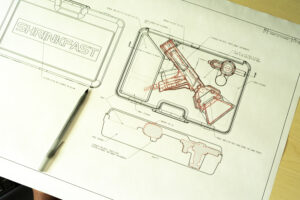

Design the Interior of the Case to Spec with Parts

Engineering will import the scanned files to our CAD software and begin the design process. PFC will produce a layout that ensures a snug and secure fit for your products.

The goal is to protect the components of each case for their longevity of use. Engineering always strives to provide the smallest, most cost effective packaging to fit our customers needs. Depending on specifications and quantity, PFC can product a custom mold interior or provide a custom foam solution.

Proof It Out in Pink Insulation Foam

As an initial Quality Assurance step, the Machine Shop will produce an interior mock-up using pink insulation foam. This quick, low-cost step allows verification of fit, form, and function without committing to expensive tooling materials. PFC can also provide samples using a CNC Foam Saw before committing to foam dies.

Test Parts

Before sending the proof to the customer, Engineering will evaluate the fit and function. The proof has to pass our detailed inspection step before proofing with our customers.

Machine the Aluminum and Finish It Up

At this point we’ll transition to machining the molds, which is on the other side of the door! The design team will provide prints and models to the Machine Shop. The Machine Shop will CNC machine mold components to meet the approved design specifications.

Insert into the Core Frame, Hang it in the Mold and Initial QA

Before releasing the tooling for sampling, the mold components are mounted in the tooling. Our Quality Assurance team inspects every component—ensuring dimensional accuracy, alignment, and fit.

With Quality Assurance complete, the tooling will be mounted in the molding machine. This sets the stage for production of your custom case.

And QA the Parts Again

The production samples undergo another round of Quality Assurance—verifying dimensions, performance, and visual standards. Only cases that pass Engineering and QA inspections are shipped to the customer for final approval.

Make Parts

PFC will begin production upon approval of the samples. Using High-Density Polyethylene plastic, our blow-molders produce cases consistent with the quality and service that PFC is known for.

Within our 20,000 square foot facility in Woodbridge, CT and our 40,000 square foot facility in Massillon, OH, we’ll store your custom tooling for future production, ready for manufacturing as needed!

From concept to completion, our modular tooling process ensures precision and performance.

We’re confident our cases will exceed your expectations—every time.

PFC has you covered.